The research or technical application of Precast Hollow Core Slab Making Machine mainly includes the following contents:

I. Research background

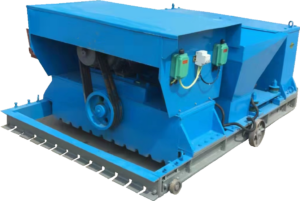

Precast Hollow Core Slab Making Machine is a specialized equipment used to produce precast concrete panels of various specifications. This equipment is widely used in the construction industry to improve production efficiency, ensure product quality, and promote the development of construction industrialization.

II. Research or application purpose

Analyze the design principle, key technology and application prospects of precast concrete panel machine to optimize equipment performance, reduce production costs and achieve sustainable development.

III. Main findings or technical features

Core design of equipment:

Forming process: Precast concrete panel machine adopts vibration compaction, rolling extrusion or sliding mold extrusion technology to ensure the density and dimensional accuracy of the panel.

Automation control: Integrated PLC (programmable logic controller) technology can realize automatic batching, mixing, forming and demoulding, significantly improving production efficiency.

IV. Production performance:

The production speed is fast, and panels of different thicknesses and sizes can be continuously formed. The production efficiency is 30%-50% higher than that of traditional processes.

The product quality is stable, the surface of the concrete panel is flat, the density is high, and it meets various engineering requirements.

Material adaptability:

Compatible with ordinary concrete, high-performance concrete and recycled concrete materials, which enhances the adaptability of the equipment.

V. Environmental benefits:

Energy-saving design is adopted to reduce energy consumption and material waste, which is in line with the concept of green production.

Support waste recycling and further reduce environmental burden.

VI. Research conclusion or application value

Precast Hollow Core Slab Making Machine improves the efficiency and quality of concrete panel production through advanced molding technology and automation system, providing important support for building industrialization and sustainable construction. Future research and development can focus on the following areas:

In-depth application of intelligent technology, such as the combination of artificial intelligence and industrial Internet of Things, to enhance the flexibility of production lines.

Adaptive design of new materials (such as lightweight concrete and composite materials).

Modular design of equipment to meet personalized production needs and reduce maintenance costs.