How to use precast concrete panel equipment and molds in construction in the Middle East and South Asia

1. Understanding Precast Concrete Solutions for Rapid Urbanization

The Middle East and South Asia are experiencing an unprecedented surge in construction due to rapid urbanization, infrastructure expansion, and population growth. Governments and developers across the region are seeking faster, smarter, and more cost-effective solutions to meet housing and commercial project demands. Precast concrete wall panels and hollow core slabs provide scalable and sustainable building alternatives that help reduce construction timelines, minimize labor needs, and ensure consistent structural quality.

These prefabricated systems are especially valuable in regions facing skilled labor shortages or extreme weather conditions. Their thermal insulation and structural efficiency make them ideal for both residential and commercial applications. To support this growing need, HENAN KELAI INDUSTRIAL CO., LTD offers a wide range of precast concrete panel production equipment, including precision-engineered precast molds, advanced extrusion machines, and complete panel forming lines tailored for regional construction requirements.

Our machinery enables builders to achieve high output with lower material waste and reduced cost per unit, making it easier to meet tight deadlines without compromising quality. Whether you’re constructing large-scale developments in the UAE or urban housing projects in India, our solutions help drive success.

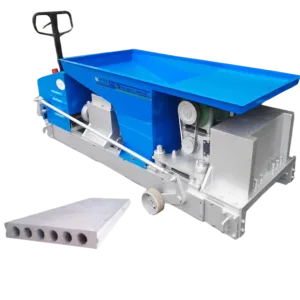

- Wall Panel Extruder: Automates production of lightweight wall panels (e.g., EPS-filled sandwich panels) with thickness control and surface finishing

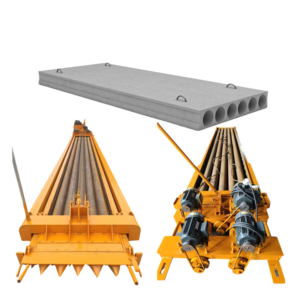

- Hollow Core Slab Molding Machine: Produces ribbed slabs with integrated voids, reducing material use by 30% while maintaining load-bearing capacity

2. Production Workflow for Lightweight Wall Panels

Step 1: Material Preparation

Mix cement, fly ash, and expanded polystyrene (EPS) aggregates in a ratio of 1:0.3:0.5 for optimal insulation and strength

Step 2: Extrusion Process

- Load mixture into KELAI extruder (4kW/mold car)

- Adjust die head to 1.3-1.7m/min extrusion speed for uniform density

- Cool panels using water jets for 24-hour curing

Step 3: Quality Control

- Check dimensional accuracy (±2mm tolerance)

- Conduct compressive strength tests (≥25MPa)

3. Hollow Core Slab Manufacturing Best Practices

The concrete hollow core slab molding machine is developed and improved on the basis of traditional manual and ground anchor pull die mold equipment. The whole hollow core slab machine is composed of a driving system(winch)and a hollow core slab mold frame. The inner slab mold is equipped with a 6-7(Depending on the slab panel width) pieces vibration tubes with vibatring cores that connect the vibrating motors. After pouring concrete into the mold, the motor drives the vibrating cores shaft to rotate at high speed and generate a strong and uniform internal eccentric vibration force. After the hollow core slabs formed, the winch will pull the mold out. And then, it starts the next slab production.

Regional Adaptation

- Add 5% silica fume to concrete mix for high-temperature resistance in UAE/Saudi Arabia

- Use fiber-reinforced polymers (FRP) in Indian monsoon zones

4. Market-Specific Applications

| Region | Key Projects | Equipment Advantages |

| UAE | Dubai Expo City District | Fireproof EPS cores meet ASTM E84 standards |

| Pakistan | CPEC Housing Schemes | 30% faster installation vs. traditional masonry |

| Qatar | World Cup Legacy Stadiums | 90% recyclable materials align with Qatar National Vision 2030 |

5. Equipment Selection Guide

For Small Factories

- KELAI extrusion line (8.5kW power) with manual mold change

For Large-Scale Production

- PLC-controlled KELAI system with 50,000-1,000,000m²/year capacity

Conclusion

By leveraging advanced precast concrete panel equipment , manufacturers in the Middle East and South Asia can meet growing infrastructure needs while achieving:

✅ 40% faster construction timelines

✅ 20% lower labor costs

✅ Compliance with ISO 15620:2019 precast standards

Explore our full range of precast concrete panel equipment at [www.kelaiii.com/www.cnkelaiii.com] to unlock regional market opportunities.

If you’d like, I can provide more details on specific models, manufacturers, or operational tips for these machines. Let me know!

If you want to buy a precast boundary wall making machine with high cost performance and good stability, choose HENAN KELAI INDUSTRIAL CO.,LTD