Revolutionizing Construction Efficiency: How Precast Concrete Manufacturing Equipment Transforms Global Building Practices

——Innovative Solutions for Modern Infrastructure Development

一. Industry Trends: Precast Technology Drives the Industrialization of Construction

With the acceleration of global urbanization, the traditional cast-in-place concrete construction model has been unable to meet the needs of efficient and environmentally friendly construction. Precast concrete manufacturing equipment is reshaping the construction industry through modular design and automated assembly line production. Taking China as an example, in 2024, the new equipment launched by leading companies such as Henan Kelai Machinery achieved a floor slab production accuracy error of ≤0.5mm and a 300% increase in production efficiency, becoming the core procurement category for infrastructure projects in Africa, the Middle East, and Southeast Asia.

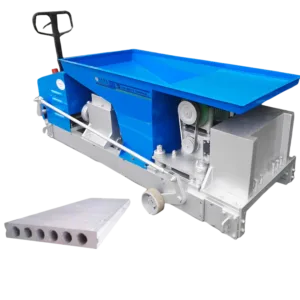

二. Analysis of core equipment technology: Precast Panel Production Machine for Construction

1. Fully automated production system

Intelligent placement and vibration: integrated AI visual positioning technology, precise control of concrete pouring volume (error rate <1%), with multi-axis vibration compaction system, bubble elimination rate of 99.8%

Multi-function mold adaptation: supports fast switching of 20+ component types such as hollow slabs, volcanic ash wall panels, U-shaped drains, etc., and mold replacement time <15 minutes

Energy-saving maintenance solution: steam maintenance energy consumption is reduced by 40%, and carbon emissions are reduced by 35%

2. Key technological breakthroughs

Patented vibration knocking technology: The automatic knocking device developed by Henan Kelai eliminates the internal stress of concrete through a spring trigger mechanism, and the compressive strength of the finished product is increased to the C50 standard.

三. Application scenarios and customer value

1. Global Engineering Cases

Highway Project: A country in the Middle East uses prefabricated automated equipment to produce 2,000 curbstones per day, shortening the construction period by 60%

Modular Housing: European customers use EPS sandwich panel equipment to build low-carbon apartments, and the wall installation machine has a construction efficiency of 200㎡/person/day

2. Return on Investment Analysis

Cost Optimization: Compared with traditional processes, the equipment investment recovery period is less than 2 years (taking an annual output of 500,000㎡ of floor slabs as an example)

Operation and Maintenance Advantages: Remote IoT monitoring system reduces the failure downtime rate by 30%, and spare parts respond globally within 48 hours

IV. Market Prospects and Strategic Cooperation

According to platform data, the global inquiry volume of precast panel production machine for construction in 2024 will increase by 217% year-on-year, with significant growth in emerging markets in Africa and Latin America.

Need help with your next project ? Get in touch before you start ! Please pay attention to our Precast concrete wall panel forming machine official website: www.kelaiii.com / www.cnkelaiii.com