Precast Wall Panel Machine: Precast compound Wall machine manufacturer Revolutionizing Construction Efficiency

–HENAN KELAI INDUSTRIAL CO.,LTD

1. Industry Background and Product Definition

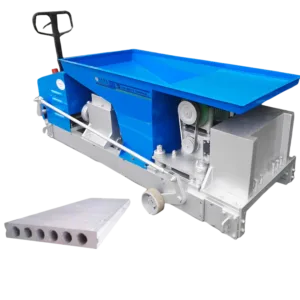

Precast Wall Panel Machine is the core equipment in the field of building industrialization, used to efficiently produce lightweight, fireproof and soundproof concrete composite wall panels. This type of equipment completes the concrete pouring, molding, curing and other processes through an automated assembly line, and is widely used in commercial buildings, industrial plants, residential projects and other fields.

2. Mainstream machine classification and technical highlights

Compound wall panel production line (Precast compound Wall Machine)

Supports adding foam core material and concrete composite structure, can customize wall panel thickness (100-380mm), length (4.2m-18m), equipped with vibration compaction system to ensure the finished product strength meets the standard.

Boundary Wall Making Machine

Specially used for the production of fence/partition panels, the modular design supports rapid mold replacement, and the daily production capacity can reach 150-200 pieces (calculated based on 600mm wide standard panels).

3. Analysis of factors affecting price (Boundary Wall Making Machine Price)

According to public data, the price range of equipment is:

Basic semi-automatic model:

8,000-120,000

Fully automatic production line: 20,000-30,000+

The price difference mainly depends on the production capacity (such as the KELAI200*900 model has a production capacity of 50 sets/month), the automation level (such as whether it contains robotic arm stacking), etc.

4. How to choose a high-quality manufacturer (Precast compound Wall machine manufacturer)

It is recommended to evaluate suppliers from the following dimensions:

Certification qualifications: ISO 9001, CE certification (such as KELAI brand);

Core technology: focus on the efficiency of the vibration system (some manufacturers use dual-axis variable frequency vibration technology to improve density);

After-sales service: give priority to manufacturers that provide installation guidance and remote operation and maintenance support (such as HENAN KELAI provides global engineer dispatch services)

5. Application scenarios and customer cases

Commercial real estate: A complex project in Dubai uses a lightweight wall panel production line, shortening the construction period by 30%;

Industrial warehousing: A logistics park in China uses fully automatic boundary wall equipment to reduce the cost of wall construction by 25%;

Government infrastructure: Southeast Asian highway projects purchase composite wall panel machinery to meet the 8-level earthquake resistance standard

African infrastructure: Egypt builds a boundary wall project.

6. Conclusion and action guide

Precast wall panel machinery is driving the global construction industry to transform towards green and high efficiency. When purchasing, it is necessary to comprehensively evaluate the balance between equipment performance and Boundary Wall Making Machine Price, and at the same time choose a Precast compound Wall machine manufacturer with technical accumulation. If you need to obtain a customized quotation or technical white paper, please contact us through our official website(HENAN KELAI INDUSTRIAL CO.,LTD ) inquiry form or directly contact our WhatsApp:+0086 17788171295