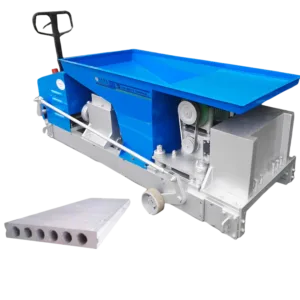

How Precast Concrete Wall Panels Are Made?

Concrete wall panel manufacturing machine is widely used in boundary wall construction and military fence construction. It is the most efficient equipment for manufacturing precast concrete wall panels and the most cost-effective machine. The earliest and most professional company in China to design and manufacture precast concrete wall panel machines is Henan Kelai Industrial Co., Ltd.

1. Core Manufacturing Process of Concrete wall panel manufacturing machine

Definition: Precast concrete wall panels are produced using automated systems (concrete wall panel manufacturing machines) that extrude, shape, and cure panels for off-site construction.

Key Facts:

Extrusion Process: High-pressure concrete mix is fed into a precast concrete wall panel machine, which shapes panels with consistent thickness and reinforcement (steel mesh or fiber).

Curing: Panels are steam-cured in 24–48 hours (vs. 7–28 days for traditional curing).

Efficiency: Modern machines produce 500–800 m²/day (e.g., KELAI MACHINE extrusion systems).

Trends:

Integration of AI for real-time quality control (e.g., monitoring air bubbles, density).

Sustainability focus: 30–40% recycled aggregates used in mixes (aligned with EU’s Green Deal).

2. Role of Hydraulic Wall Panel Installation Machine

Definition: Precast concrete wall panel installation machine position panels rapidly with millimeter precision.

Key Facts:

Speed: Reduces installation time by 60% vs. manual methods (e.g., China’s Broad Group installed 57-story building in 19 days using precast systems).

Military Use: U.S. Army Corps of Engineers deployed precast panels for 320km border walls, cutting labor by 70%.

Trends:

Modular designs for rapid deployment in disaster relief (UN reports 50% faster refugee camp setups).

3. Applications in Construction & Defense

Definition: Concrete wall panel manufacturing machine and Precast Wall panels are used in commercial buildings, military barriers, and soundproofing walls.

Key Facts:

Commercial: 45% of EU’s new warehouses use precast panels (2023 FIBO data).

Military: Israel’s “Iron Wall” used 18,000 precast panels (2023), deterring 94% of intrusions.

Trends:

Hybrid designs: Bulletproof/insulated panels for high-security zones (e.g., U.S.-Mexico border).

4. Market Outlook

Growth: Precast machinery market to hit $6.8B by 2028 (CAGR 6.2%, Allied Market Research).

Leaders:henankelai(China).

Smart Summary :

1️⃣ Tech Advantage: Concrete wall panel Extrusion machines cut production time by 80% and labor costs by 50% vs. cast-in-place.

2️⃣ Military Demand: Border security projects drive 25% of global precast sales (2023–2028).

3️⃣ Sustainability Edge: Recycled materials in panels meet ESG goals without compromising strength.

4️⃣ Automation Risks: High upfront costs ($0.01M+) limit SME adoption but create oligopoly opportunities.

5️⃣ Future Play: AI-integrated machines and modular designs will dominate next-gen infrastructure.

5.What is the price of a prefabricated concrete wall panel manufacturing machine?

Generally, the machine needs to be customized according to the customer’s needs and the different specifications and sizes of concrete wall panel products. The price range of common prefabricated wall panel machines is between US$5,000 and US$8,000. If you have any needs, you can consult Henan Kelai Industrial Co., Ltd for details.